Sab ko clearly dikh raha hai ki prices hike ka direct benefit customers or car manufacturers dono par ho raha hai. Electric cars ki taraf shift hone ki wajah se, jismein expensive onboard batteries, environmental or technological requirements, or components or raw materials ke rising cost include hai, cars ki prices kaafi high ho gayi hai.

That's the reason car manufacturers production ke time pe jitna ho sake cost cut karne ki try karte hai. Isme production process ko simple banana sabse important hota hai, or yahi par ek concept ka role aata hai maybe aap familiar na ho, "gigastamping."

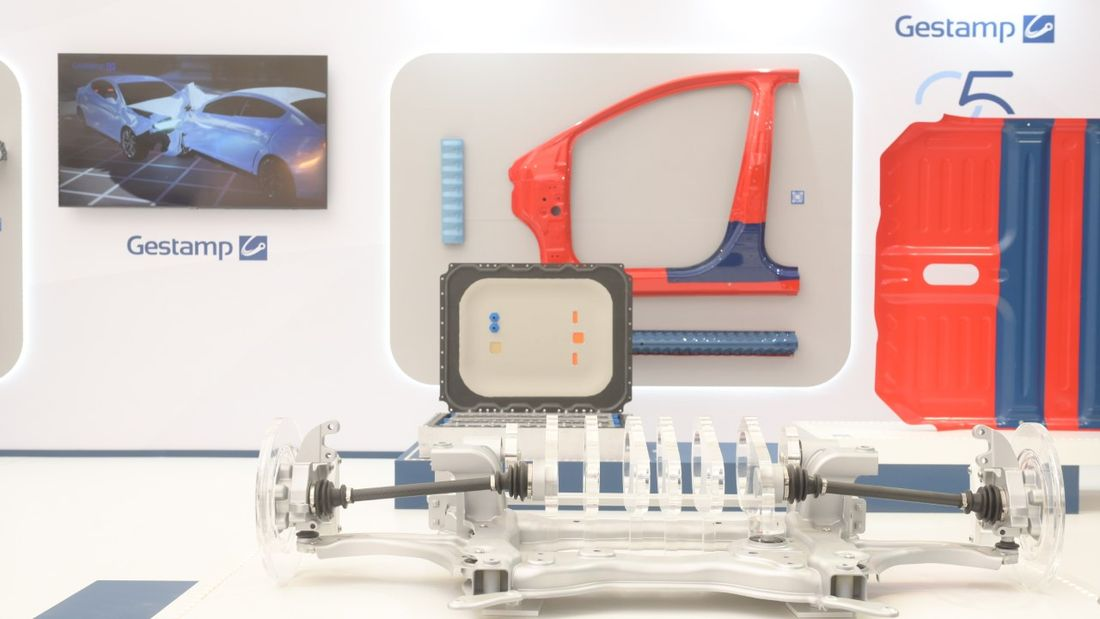

Image Courtesy: Motor.es

This is low-cost gigacasting

Ye last etrm aapne pehle bhi suna hoga: "gigacasting". Tesla ne isko popular banaya tha apni cars ke manufacturing process mein. Basically, isme massive industrial presses use hote hai jo ek hi baar mein big structural aluminum parts cast kar dete hai. Isse parts ki counting kaafi reduce ho jaati hai, assembly simple ho jaati hai, or overall cost bhi low aati hai.

Jaise example ke liye, gigacasting mein kya hota hai ki 80 ya usse zyada different parts make ke instead, ek hi big single piece bana diya jata hai by pouring liquid aluminium into a gigapress.

Tesla ke baad, Volkswagen, Volvo, Toyota or Chinese companies jaise Xpeng, NIO or Zeekr ne bhi ye trend follow karna start kar diya.

But Stallantis or Renault Group jaise big giants ne is idea ko mostly reject kar diya. Reason simple hai: ismein massive investment lagti hai or process kaafi expensive hai. so most of the European manufacturers (sab nahi) ek affordable option choose karenge, jise "gigastamping" kaha ja raha hai.

Tesla popularized gigacasting, but Europe is exploring alternatives like gigastamping (Image Courtesy: Motor.es)

Gigacasting koi fast growing trend nahi hai. Actually hum gigastamping ka use zyada dekh rahe hai, matlab ek hi pass mein ek big part stamp karna or 20-25 different parts ko replace kar dena.

Ye baat Francisco J. Riberas ne kahi hai, jo Gestamp ke CEo hai, Gestamp ek Spanish multinational company hai jo cars ke liye metal components design, develop or manufacture karti hai.

Spanish company ke according, gigastamping hi future ka solution hai, because ye gigacasting se zyada economical option deta hai or isme risk or financial investment bhi kaafi kam hota hai compared to gigacasting.

Customer hum par kaafi pressure exert karte hai cost reduce karne ke liye, or ye un solutions mein se ek hai. Part jitna large hota hai, customer ke liye utna hi easy hota hai. Aur jab few parts hote hai, then unhe kam develop karna padta hai, less validate karna padta hai, or purchase bhi less karna padta hai, "aisa kehna hai Gestamp ke bodywork director Xavi Herrera ka.

Basically, ye "low cost gigacasting" ka matlab hai ki pehle hi components ko weld kar diya jata hai, or baad mein unko stamp karke ek single piece bana diya jata hai. Isse stamping line zyada complex nahi hoti or example ke liye, aluminum ke instead affordable steel use karna possible ho jata hai.

For example, Gestamp ek double door frame pe work kar raha hai jisme C-pillar integrated hota hai, or ek "door ring" bhi develop kar raha hai jisse A or B pillars ko ek saath combine kiya ja sakta hai.

Technology use karne ka ye new method ek or cheez bhi show kar raha hai, whether, humein pasand ho ya na, Europe or China ke between clear difference. China jaise Asian giant mein manufacturers ko affordable financing mil jaata hai, jisse wo expensive gigacasting machines easily purchase kar sake. Wahi Europe mein companies ko existing platforms se hi use mein karna padta hai or unke paas capital bhi kaafi limited hota hai.