Ek bigger concern society mein ye hai ki electric car ki batteries degrade ho jaati hai (or unko replace karna bhi kaafi expensive hota hai), jaise mobile phones or other electronic devices ki batteries time ke saath weak ho jaati hai. China mein lagta hai ki unke paas ek solution hai jo battery ki useful life recover kar sakta hai.

Recently observe kiya gaya hai ki kuch modern batteries apne manufacturers ke initial estimate se zyada jaldi old ho jaati hai. because US ke University of Chicago or Argonne National Lab or China ke Huazhong University of Science and Technology ke researchers ne joint research kiya hai.

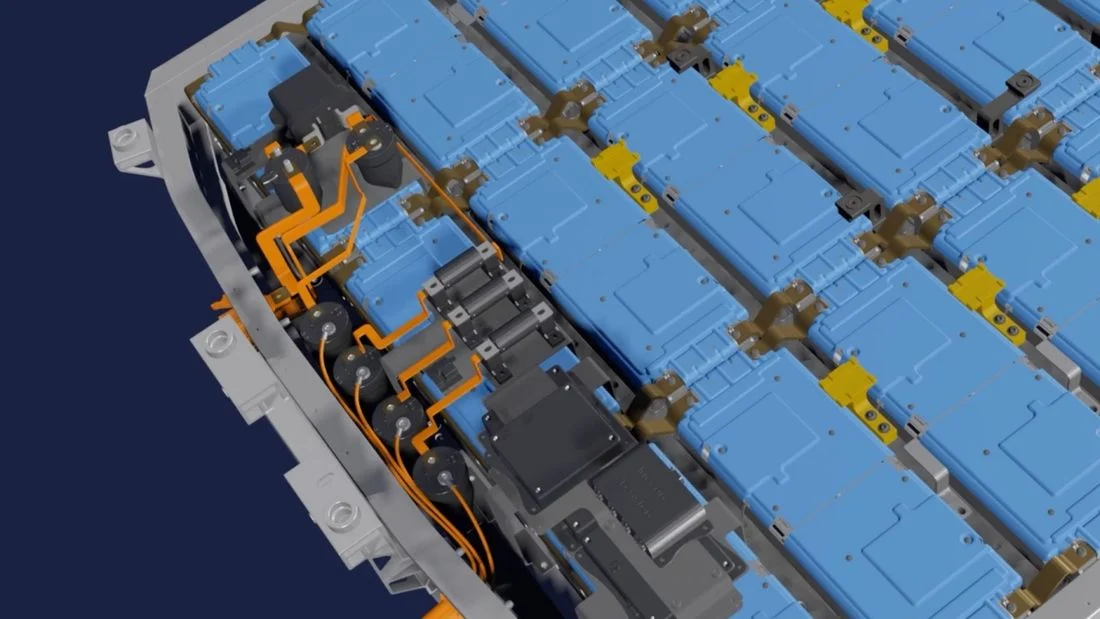

How to restore batteries in electric cars

Image Courtesy: Motor.es

US side se jo explanation hai, wo simple hai ek mistake ho gayi. Jo conclusions polycrystalline cathodes ke liye valid hai, woh monocrystalline cathodes pe apply nahi hote, jo nowdays kaafi electric car batteries mein use ho rahe hai. Study ye batati hai ki charge-discharge cycles ke during inmein uneven reactions hoti hai, jisse stress build hota hai or potentially structure fail hone ka risk hota hai.

Ab tak batteries recycle karne ke jo methods use ho rahe the, wo kaafi aggressive hote hai or mostly original structure ko damage kar dete hai. Real game NCM811 cathode ka hai, charging or discharging ke repeated cycles mein ye gradually lithium lose kar deta hai, jisse uski stability or capacity dono pe effect padta hai.

Melted salt in a lithium flavored bath

China mein past kuch years se electric or plug-in hybrid cars bahut zyada aa chuki hai. Is wajah se ab gradually old hoti batteries ka number industrial level pe kaafi increase hone wala hai. Because battery ko regenerate or recycle karne wali technologies develop karna bahut important ho gaya hai. Agar aisa nahi hua, then new batteries ke liye cobalt or nickel jaise metals nikaalne ke liye or zyada mining karni padegi.

Image Courtesy: Motor.es

China mein jo unhone kiya hai, usme batteries ko ek liquid mix ke bath mein daala jata hai, jisme lithium hydroxide, lithium nitrateor lithium salicylate (jo ek neuroactive lithium salt hai) hota hai.

Is mix ko heat karke liquid state mein laate hai, phir lithium ions freely move karne lagte hai. Ye ions battery ke inner jahan structure damage hota hai wahan tak pahunch jaate hai, gaps fill kar dete hai or monocrystalline cathode ki structure ko wapas theek kar dete hai.

After 200cycles, 76% of the capacity was preserved

Ye results show karte hai ki 200 charge discharge cycles ke baad battery ki approx. 76% capacity wapas recover ho gayi, or saath hi composition ki surface bhi kaafi uniform ho gayi.

Ab tak jo recycling methods use ho rahe the, unka main benefit sirf metals recover karna tha, but battery ki actual funtionality wapas laana possible nahi hota tha.

Is process se environment ke liye harmful waste reduce hota hai, cobalt or nickel mining ka pressure bhi reduce hota hai, or battery production ka ek biggest weak point address ho jata hai. Basically, ye circular economy ko close karta hai, because already refined materials ko hi again use kiya jaata hai, jo pehle se system ke inner already hote hai.

Image Courtesy: Motor.es

Battery recycling and the circular economy

Bilkul old ya worn-out battery bhi, whether wo NMC ho ya LFP apni basic structure maintain karti hai, jisse controlled conditions mein dobara restore kiya ja sakta hai.

That's why battery recycling mein kaafi interest hai, CATL or BYD jaise global leaders se lekar Shanxi Coking, Yunnan Tin, or chemical/refining focus wali companies jaise Huayou Cobalt, New Energy Zhongneng, Ganfeng Lithium or Haopeng Technology tak.

Abhi tak jo result mile hai, wo sirf laboratory level par mile hai, means experimental phase mein hi process chal raha hai. later isse optimize karna padega so that ye industrial scale par use ho sake or battery recycling industry par real impact daal sake. Europe ke liye ye or bhi important ho jaata hai, especially agar wo apni battery supply chain par itna dependent nahi rehna chahte jaise abhi hai.